CONSERVATION OF LEATHER AND TEXTILES FROM THE DEFENCEKenneth Morris, & Betty L. Seifert

3 A CASE STUDY: A SHOE RECOVERED IN NON-ASSEMBLED ASSOCIATED FRAGMENTSAMONG THE ARTIFACTS recovered during the 1977 DEFENCE field season was a shoe (ca. 24 cm. long). Even in the cold, thick mud at the wreck site, thread which had originally secured the various shoe parts deteriorated, and the artifact was retrieved in sections. The “upper” was made from leather comparable in weight (ca. 2 mm. thick) to that found in a modern shoe. Several layers of leather ranging in thickness from 2 to 4 mm. were sewn together into a sole and heel. Iron staining could be seen on the surface of the leather, and when a section prepared with a freezing microtome (thickness ca. 5 microns) was viewed under magnification (100�), the intrusion of foreign matter into its structure was obvious. In this case, however, the accumulation of metal salts had not become thick enough to severely embrittle the leather. Before treatment, the shoe parts and their identification numbers (embossed on a Teflon tape or written on a strip of Tyvek6) were sewn between two pieces of fine nylon net. This encasement secured the leather fragments and their registration numbers so that they would not be confused or misplaced during treatment. The leather was kept in water at all times prior to treatment. Mold growth was curtailed by recirculating cold water (directly from the tap) through the leather holding tanks on a regularly (daily) basis. 3.1 Treatment of the ShoeTREATMENT BEGINS by washing in de-ionized water to remove soluble salts. After removing these salts, leather which had been stained or encrusted with metallic salts was placed in a 5% (w/v) solution of oxalic acid in de-ionized water until the stain or encrustation dissipated. The leather was then thoroughly washed with tap water for several days. This procedure for removing encrustations was proposed by Tilbrooke and Pearson.7 Their treatment was designed for textiles, but in this case it was found useful when applied to leather. A freeze-drying process for leather developed by Rosenquist8 makes use of polyethylene glycol 400, but does not mention surface treatment or consolidation. At the MSMRCC, a modified freeze-drying treatment uses PEG 1500.9 The process includes the following steps in sequence: impregnation, drying and surface treatment, followed by consolidation, support, and reconstruction when necessary.

A. E. A. Werner, as abstracted by B. Muhlenthaler, used PEG 1500 at an elevated temperature of 40�C.10 Initially, this method was attempted, but the leather from the DEFENCE became hard and brittle. Further research showed that this method may be undesirable under any circumstances because elevated temperatures may have an adverse effect on leather.11,12 An aqueous solution of PEG 1500 at room temperature proved an effective impregnation treatment for waterlogged leather.

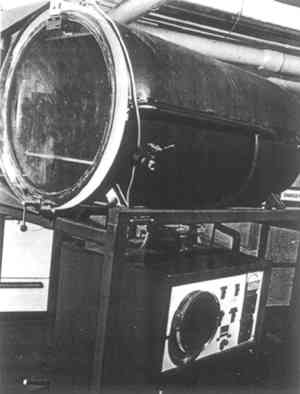

This schedule allowed the leather and the frozen water within an opportunity to acclimate to lowered pressures. From empirical observations, a gradual reduction in pressure minimizes the amount of surface disruptions in the leather. After three days, the pressure of the drying chamber was reduced to the limits of the unit (ca. 5 microns). The drying phase was complete when no ice was deposited on the condenser.

3.2 Consolidation or Addition of Auxiliary SupportEVEN AFTER LEATHER has been impregnated and freeze-dried, it is important to correct problems within its structure prior to reconstruction of the artifact.

Although no difficulties were encountered with the Leather Dressing, B-72/Ethanol interface, B-72 in Acetone or Xylene might be substituted to overcome any incompatibility. Initially this darkens leather slightly, but after the solvent evaporates, the resulting color is not significantly different from its appearance before consolidation. This application is repeated until the area does not readily accept the resin mixture.

The pre-treatment serves two purposes: first, on top of the surface dressed with the British Museum Leather Dressing the B-72 enhances adhesion, and second, the resin coating is easily reversible. 3.3 Assembling the Parts for Display and StudyWHEN STABILIZATION was complete, the shoe was reassembled (Fig. 3). Using the holes from the original stitches, each part was sewn with dark colored cotton thread which had been coated with a microcrystalline wax. When sewing was not possible because the stitch holes had been mutilated, parts were adhered using a process similar to the one described for supporting a disruption.

|