TREATMENT AND MOUNTING OF A POSTER ANGLETERRE BY A.M. CASSANDREAntoinette Owen

ABSTRACT—This article describes the examination, treatment and mounting for exhibition of an oversize work of art on paper. The unusual dimensions and the nature of the medium of this lithograph created certain logistical problems in treatment. Rather simple procedures such as water washing, wet handling, flattening and mounting were complicated by the dimensions of the object. The use of enzymes to facilitate a backing removal and the application of a new backing required revising known approaches and techniques. 1 INTRODUCTIONADOLPH JEAN-MARIE MOURON (French, 1901–68), known as A.M. Cassandre, helped to elevate the craft of commercial advertisement to the fine art of poster design. Active in the 1920s and '30s when Fauvism, Cubism and Futurism, although no longer the avant-garde, influenced all aspects of art and design, Cassandre was one of the earliest poster artists to understand that the images, uses of color, and theories that developed from these movements could enhance the impact and effectiveness of the poster's commercial message. Cassandre refused to fill space with any but the most essential copy and relied instead on the power of design to fix the public's attention on the advertised product. His posters were sometimes designed especially to be seen from a distance and were often mounted on building walls; these particular posters are very large, up to 13′ � 15′ on occasion. In 1978, the Hirshorn Museum and Sculpture Garden was given one of Cassandre's travel posters entitled Angleterre; it was designed, as were many of his posters, with only a single word designating the message. Angleterre, published in 1934, is a multicolored lithograph on lightweight, wove paper. Fiber analysis and microchemical tests indicate that the paper is a chemically purified wood pulp. Eight colors of ink (probably oil-based) were applied to the paper in the following order: white, yellow, yellow-green, forest green and pink (the latter two appear to have been applied during the same printing), black and brown (also applied at the same time), and lastly gray. The poster is made up of four equal quadrants of individual sheets of paper, each ca. 5′ by 4′. When first examined in the conservation laboratory, the poster was in two vertical strips, each strip 10′ by 4′. Quadrants 1 and 2 (see Fig. 1) were attached to each other bottom to top and backed to a cotton cloth with a starch-based adhesive (as indicated by the reaction of the iodine/potassium iodide stain described in B.L. Browning's Analysis of Paper). Quadrants 3 and 4 were attached and backed in the same manner. The two vertical strips had once been joined to each other side to side.

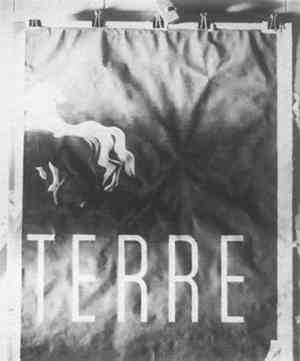

Examination of Angleterre revealed the following: the application of the cloth backing to the poster created overall distortions and small sharp creases in the poster. Raking light examination revealed an uneven attachment between cloth and poster in numerous areas. These air pockets created the large overall distortions in the poster (Fig. 2). The heavily inked portions of the poster differed in expansion and contraction rates from the cloth as well as from the uninked portions of the poster (the borders). During the backing procedure, the inked area of the poster (the design area) contracted

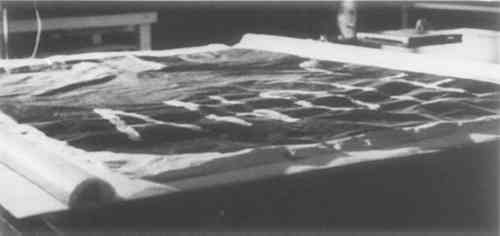

The dimensions of this object created certain logistical problems in its conservation treatment. Not the least of these was creating a space in which to wet and bathe the poster as well as providing an adequate support for handling the object when wet. Other concerns were designing a lining or backing procedure for each large quadrant which would provide enough tension during drying to pull out the creases and distortions caused by the previous lining, while at the same time avoiding too much tension over such a large area. The final questions to be answered were ones of mounting, display and storage. 2 TREATMENT OF QUADRANT #2THE BOTTOM LEFT QUADRANT, referred to as quadrant 2 in Fig. 1, was the first of the four quadrants treated. The vertical strips (quadrants 1,2 and 3,4) were separated into quadrants by applying moisture to the overlapping sheets. The surface of quadrant 2 was dry cleaned with finely powdered eraser crumbs to remove the surface dirt. Pressure-sensitive tape was removed either mechanically or by using acetone if the Separating the poster from the cloth was the first step in structural treatment. So that the poster and backing could be soaked in water, a large washing tray was constructed of polyethylene sheeting supported at the sides by wooden 2-by-4s joined together with metal right-angles and screws. A rigid fiberglass screen stretched onto a wooden frame was constructed as a support for the paper quadrants during aqueous treatment. Quadrant 2, supported face down on the screen and cushioned with a sheet of wet strength tissue, was placed into the tray and allowed to soak in deionized water1 (brought to pH 8.5 by the addition of calcium hydroxide solution) for 1� hours. Attempts to remove the cloth were then begun. This process was more difficult than anticipated; the adhesive was thickly applied and in many areas the water did not by itself loosen the bond between cloth and paper. If mechanical manipulation of the cloth did not release the bond in these tenacious areas, the cloth was cut out and left attached to the verso of the poster. In most areas the cloth could be removed after prolonged soaking and manipulation; a gray adhesive layer contaminated with wood chips and other accretions was noted. When the cloth backing was finally removed, the poster was placed in a fresh water bath and allowed to wash another 1� hours. It was hoped that this bath would reduce the starch adhesive. However, upon removal from the bath and air drying, the poster was extremely distorted (Fig. 3). Two types of distortions were now evident:

It was felt that the overall distortions could be remedied by dissolution of the adhesive from the verso, while the inherent distortions created by the ink layers could be remedied by a friction/tension drying method. The tenacious adhesive was resistant to warm, alkaline (pH 8.5) water, and the paper had little wet strength to withstand scraping of the adhesive. Tests made with enzymes specific to starch indicated that the adhesive would easily break down under enzymatic action without affecting the paper or inks. The enzyme selected for the treatment was Alpha Amylase type IIA (bacillus subtilis) from Sigma Chemical Corporation.2 This enzyme operates most efficiently at a solution pH of 6.9 and within a temperature range of 37–39� C. Chemical buffers are often recommended to maintain the proper solution pH because often the acidity of the art object, if it remains in an enzyme solution for an extended period of time, will shift the solution pH. In this case, however, the type IIA enzyme solution was found to work extremely efficiently without the addition of the sodium phosphate buffer solution. A possible explanation may be the rapidity of enzymatic action with type IIA (15 minutes for each 5′ by 4′ quadrant using a .01% solution at 39�C). In the short period of time necessary for the enzyme to hydrolyze the amalose fraction of starch, the pH may not have begun to shift significantly. It should be mentioned that the enzyme solution used was given a slightly higher pH initially (7.2 with calcium hydroxide solution as opposed to 6.9 recommended in the literature), with the expectation that dissolution of the adhesive into the solution would cause a drop in pH. Quadrant 2 was treated with a .01% solution of Alpha Amalase type IIA. At the end of 15 minutes, tests made on the verso using the iodine/potassium iodide stain indicated that the amalose chain of the starch was completely hydrolyzed (no blue/purple stain was visible). The quadrant was rinsed, water washed for 1� hours, then dried between blotters. A comparison (Fig. 4) with the earlier photograph (Fig. 3) shows that the overall distortions disappeared, with only those around the letters remaining.

3 THE ENZYME PROCEDUREREMOVAL OF THE CLOTH BACKING and tenacious starch was easily accomplished on the other three quadrants. The procedure used was as follows: The large tray was placed on the surface of the vacuum hot table and the table was warmed to 39�C. A small amount of water was placed in the tray to conduct the heat. The quadrants, face down on the cushioned support, were placed in the tray. The enzyme solution, warmed to 39�C and with a pH of 7.2, was brushed onto the cloth. A sheet of polyethylene was used to cover the entire tray in order to maintain the temperature. The average length of time for successful enzymatic action was 15 minutes, after which the cloth was usually found to be detached from the paper. Tests with the iodine/potassium iodide solution indicated whether any residual starch remained on the paper. After rinsing the quadrants for � hour in a water bath followed by a second rinse with running water, they were allowed to air dry. The verso was then sprayed with ethanol to deactivate any residual enzyme. The quadrant was then turned face up on the screen and given a water bath (pH 8.5 with the addition of calcium hydroxide solution), again employing the surface of the vacuum hot table to slightly warm the water. It was felt that any residual enzyme or minute amount of starch, as well as paper degradation products, would be encouraged to diffuse from the paper by this warm, alkaline water bath. An interesting observation was made during water washing the quadrants. The sharp creases mentioned earlier remained in the ink and paper during submersion in

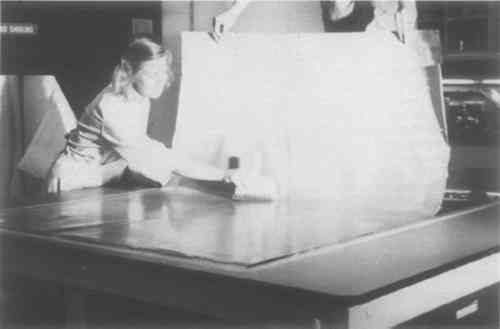

All pulp fills and tear repairs were completed before backing. Areas of loss were compensated with rag paper pulp; the entire quadrant was wetted onto mylar during the pulping procedure, the sections to be filled were placed over a light box. Because many areas of loss abutted tears, the tears were aligned and secured verso with small Japanese tissue patches before backing in order to complete the pulping procedure on all losses. 4 BACKING TECHNIQUEGIVEN THE NUMBER OF LOSSES at the edges, the tears, and the general weakness of the paper, it was desirable to back the quadrants. A backing technique was selected that would involve a lateral drying tension of the quadrant in order to ameliorate the remaining ink/paper distortions. A sheet of .002 gauge Mylar was cut to the dimensions of the quadrant and smoothed onto a flat table surface. Strips of masking tape were laid down on the table surface 1� inches beyond each edge of the Mylar, as guidelines during the backing procedure. The quadrant was slowly wetted and brushed face down into smooth contact with the Mylar (Fig. 6). It required thorough saturation and some brushing manipulation to flatten the distortions and creases. When finally smooth, the quadrant had expanded a great deal.3 The backing procedure, therefore, was not begun until the flat quadrant had become damp rather than saturated and thus contracted almost to its original dimensions (using the Mylar to

As the tissues dried, a lateral stretch or drying tension was created. If the quadrant had been backed when fully expanded, the tension created probably would have caused damage either by tearing the poster or at the least separating repaired tears and pulp fills. The degree of tension of the quadrant was controlled by the degree of expansion of the quadrant at the time of backing. The Usugami tissues were fully wetted, then blotted of excess water before application. Backing with this system, although necessary because of the distortion problem, depended a great deal on judging the “moment of truth”, i.e. timing was essential. Drying of the poster was aided by application of large blotters and weights. All moisture was removed from the reverse. The blotters were changed periodically until the quadrant was completely dry. When removed from the tension system, each quadrant was flat and without distortions.4 5 MOUNTING THE POSTERTHE POSTER WAS ORIGINALLY INTENDED to be viewed mounted and flat. In keeping with this intention it was decided to mount the quadrants onto a ragboard-surfaced aluminum Hexcel panel. The panel was built to be several inches larger in each dimension than the assembled poster. Several sheets of oversize ragboard, bevel-cut at joins to eliminate uneveness and effect a continuous surface, were attached to one side of the aluminum panel with Beva 371. The ragboard surface was then given a light and even spray of Beva 371 in toluene. The spray was applied under high pressure, which helped to create, along with the rapid evaporation of the toluene, a spider web or flocked layer of adhesive on the ragboard surface. It was felt that this method of application enabled a type of nap bonding to take place between the Usugami tissue and the ragboard. The vacuum hot table was used to attach the poster to the panel; only minimum heat (140�F) and pressure were necessary. The pulp fills were toned with Liquitex acrylic paint. This paint, though not reversible, simulates lithographic inks very well. Toning of the tears and other original paper surfaces such as abrasions was accomplished with Winsor & Newton watercolors and Grumbacher pastels. The poster was displayed in an Art Deco poster exhibition soon after treatment was completed (Fig. 8). Although the aluminum panel was probably the lightest rigid support possible, the additional weight of a wooden frame and �-inch Plexiglas created a very heavy package. Therefore, the Plexiglas was attached in such a way that it can be removed from the frame and panel during storage. The poster is stored on a steel rack in the painting storage area of the Hirshhorn Museum.

NOTES1. Culligan deionizing system-anion/cation exchange columns, two prefilters and a neutralizing column filled with calcium carbonate chips. Normal pH of this water without the addition of calcium hydroxide solution is approximately 7.4 as measured by the E.M. Merck indicator papers. 2. If possible, it is desirable to choose a purer grade enzyme over the crude grades. Of the two bacillus subtilis amylases available from Sigma, there is Type IIIA cited in the literature, which is a crude grade and, although free of foreign extenders, contains extraneous protein material, and Type IIA. Type IIA has been 4X crystallized. Alpha Amylase's ability to hydrolyze starch is measured in activity units. One unit will liberate 1 mg maltose from starch in 3 minutes at pH 6.9 and 20�C. While Type IIIA has approximately 73 units/mg protein, the refined Type IIA has a specific activity of approximately 1,350 units/mg of protein. Reaction time is often much quicker with this preparation and it requires only 1/10; the concentration as the crude grade. 3. The paper expanded approximately �″ on all sides; but an exact measurement was not taken. 4. Each quadrant remained in the tension system for approximately seven hours. The inks were unaffected by this system. One concern had been the possibility of blanching caused by moisture trapped between the ink layer and Mylar. Tests with smaller expendable posters on equally thin paper, indicated that all moisture could be successfully withdrawn from the poster's verso. ACKNOWLEDGEMENTSIWOULD LIKE TO THANK my fellow conservators in the Hirshhorn Museum conservation laboratory for generously allowing me the extra space necessary for a project this size. Susan Lake deserves special thanks for her valuable assistance with this treatment. REFERENCESBrown, Robert K. and Reinhold, Susan. The Poster Art of A.M. Cassandre. E.P. Dutton, New York, 1979. The Museum of Modern Art. Posters by Cassandre (catalogue of the exhibition with forward by Ernestine M. Fnatl). New York, 1936. Barnicoat, John. A Concise History of Posters. Oxford University Press, New York and Toronto, 1972. Delhaye, Jean. Art Deco Posters and Graphics. Rizzoli International Publications, Inc., New York, 1977. Segal, Judith and Cooper, David. “The Use of Enzymes to Release Adhesives.” The Paper Conservator, 2 (1977). Gratten, David W., St.Hilaire, Johanne, Burgess, Helen, and McCawley, J. Clifford. “The Characterization of Enzymes for Use in Paper Conservation.” The Cambridge Conference Preprints, 1980. Correspondence and telephone conversations with Dr. William Jacoby, an enzymologist at the National Institutes of Health, Bethseda, Maryland.

Section Index Section Index |