QUANTITATIVE STUDY: THE EFFECTS OF SIZED MATERIALS AND “DRYING TIME” IN THE USE OF LASCAUX 360 HV AS A LINING ADHESIVEDanielle Allard, & Kenneth B. Katz

ABSTRACT—Empirical use of Lascaux 360 HV as a lining adhesive indicates that the bonds produced can vary significantly depending on the parameters chosen. In this research bond strengths of linings were quantitatively measured by peel and lap/shear tests. The influence of the amount of time between application of the adhesive and lining (1 hr. -vs- 24 hrs.) was evaluated as well as the effects of sizing applied on the original canvas and/or lining material. Results confirm significant quantitative changes in peel and lap/shear tests depending on the parameters chosen. 1 INTRODUCTIONSINCE THE EARLY '70's, acrylic dispersions have been used increasingly as non-penetrating lining adhesives. Their ease of application and relatively low toxicity have contributed to their gain in popularity. One acrylic dispersion that is used by conservators in the United States is Alois K. Diethelm's AG Lascaux 360 HV. In addition to the properties mentioned above, it comes in a form ready to use and has a low activation temperature. Empirical use seemed to show that a wide range of bond strengths could be produced by varying the lining conditions, i.e., heat or solvent activation, pressure, “drying time,” sizing of materials. Quantitative experiments have confirmed some of the above.3,7 The purpose of this project was to measure and compare bond strengths obtained when lining under varied parameters, using Lascaux 360 HV as the adhesive. Bond strengths were measured by peel and lap/shear tests. The lining parameters chosen were based on previous quantitative testing and empirical use of the adhesive in the lining of paintings. Quantitative tests of Lascaux 360 HV have shown that sizing the original canvas with Acryloid B-72 increases the strength of bonds.3 Furthermore, empirical use has indicated that sizing the lining canvas also affects the bonds strength. Another qualitative observation has indicated that the “drying time” of the adhesive influences bonding. It has seemed that the bonds produced, when lining with Lascaux soon after it was dry to the touch, are stronger than the bonds produced when allowing for a longer period of time between application and lining. This experiment tested the influence of two lining parameters:

First, peel and lap/shear results were compared between linings performed 1 hour and 24 hours after application of the adhesive. One hour was chosen because it seemed to be the approximate time it took for the adhesive to become translucent and not wet to the touch. Twenty-four hours was chosen because it was assumed to be long enough for the dispersion to lose most of its water. Also, based on personal observation, twenty-four hours is a reasonable length of time a Second, peel and lap/shear results were compared among linings where the original canvas was sized or unsized and/or the lining canvas was sized or unsized. The sizing material was Rohm and Haas Acryloid B-72. When non-penetrating adhesives are used in the lining of paintings, these latter sometimes need to be consolidated in a separate procedure. The use of acrylic resins for this purpose has been mentioned.1,2,5,6 Mehra5 uses a 5 to 10% solution of Rohm and Haas Plexisol P-550 (polybutyl methacrylate). Two advantages of using an acrylic resin over a wax-resin mixture is that the acrylic resin will not darken even a thin paint film and retains some flexibility in the original canvas. In this experiment, Acryloid B-72 was chosen for its known stability and because it is sometimes used as a consolidant for paintings. 2 EXPERIMENTTHE SUPPORT USED AS THE original canvas was a light-weight Belgian linen. The Belgian linen was stretched, wetted and restretched again. After the second stretching, one coat of Liquitex Acrylic Gesso was brushed on to simulate a ground. A few days later, Rohm and Haas Acryloid B-72 (10% in xylene) was applied to the reverse of half of the Belgian linen samples, followed by a second coat one day later. The lining canvas in all cases was a woven polyester, P & S #39. The polyester was stretched and half the samples were coated with 10% B-72 in xylene. One coat of B-72 was brushed on each side of the polyester samples. The lining adhesive was used undiluted from its container and applied to the polyester through a fiberglass window screen using a squeegee. A second coat was applied in the same manner, approximately two hours after the first application. The final application of adhesive (1 hour and 24 hours drying time) was arranged so that all samples could be lined at the same time and under the same conditions. The samples were lined on a Nascor Convectron Vacuum hot table using Mylar (.001mm), as a membrane. The vacuum as measured on the table gauge was approximately 4 inches of Hg. (By “feeling” the top membrane, the vacuum pressure was determined not to be very strong but adequate.) The temperature of the adhesive, as measured with a digital temperature meter, was approximately 131�F (26�C). It was kept constant for 5 minutes. The samples were rolled once using a nappy paint roller. The table was then cooled down to room temperature. The samples were on the table for a total of 2 hours. The samples were lined to produce 1 “overlap for lap/shear testing and 3” overlap for peel testing. Four samples were lined for each category and labeled as follows:

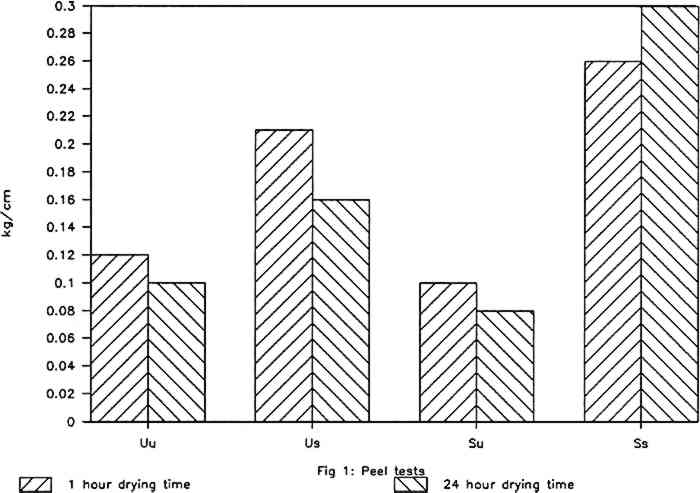

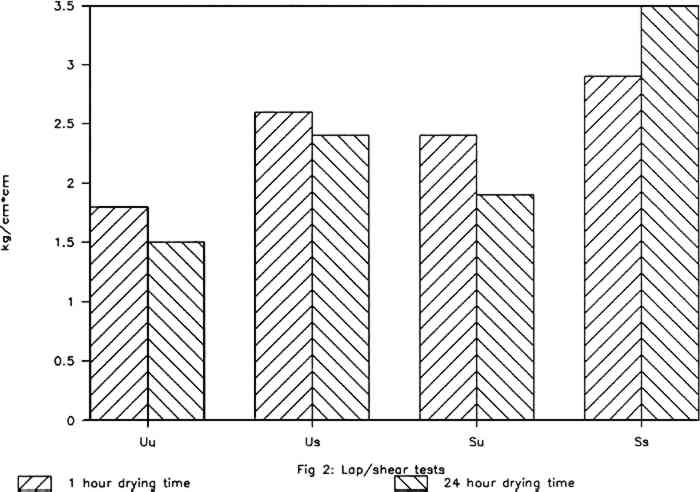

The number represents the elapsed time between the final application of the adhesive and the actual lining: 1 for 1 hour, 24 for 24 hours. The capital letter represents the polyester: S for sized with B-72, U for unsized. The lower case letter represents the linen: s for sized with B-72, and u for unsized. As an example, P1 Su represents peel test of the samples lined 1 hour after the final application of Lascaux 360 HV. The polyester was sized and the Belgian linen unsized. After lining, the samples were cut into 1″ wide strips and sent to the Nordson Corporation testing facility in West Lake, Ohio where peel and lap/shear tests were performed on an Instron 1115 Tester. The conditions were as follows for the test: Peel test: 50 Kg load cell crosshead speed 2mm/min. chart speed 2mm/min. Lap/shear test:50 Kg load cell crosshead speed 1cm/min. chart speed 1 cm/min. All samples were climatized to 72�F and 55% Rh.3 REPORTING OF THE DATATHE DATA FOR THE peel tests were calculated by averaging the results of the four test pulls. Maximum values were obtained by calculating the means of the highest peaks on the graph read-out and the minimum values were calculated by averaging the lowest points. The average values were determined by calculating the means of the maximum and minimum values. (The smaller values to the right of each number represents the standard deviation). The lap/shear results were obtained by recording the peaks on each of the four runs and averaging them together. The standard deviations were also calculated. 4 DISCUSSIONAS CAN BE SEEN in the tables and graphs, quantitative differences in peel and lap/shear strengths were noticed when the two tested lining parameters were varied. It can be safely assessed that sizing the original canvas does increase bond strength. Table 1 shows that the values obtained with the samples of sized Belgian linen (s) were consistently higher than the values obtained when the Belgian linen was unsized (u). 1 Us (unsized polyester-sized linen) has an average peel strength of .21 Kg/cm compared to 1 Uu (unsized polyester-unsized linen) which has an average peel strength of .12 Kg/cm. Also 1 Ss (sized polyester-sized linen) has a value of .26 Kg/cm which is higher than the .10 Kg/cm value obtained with 1 Su (sized polyester-unsized linen). Test results from samples dried for 24 hours were also consistent in this trend. Table 1 Summary of Data for Peel Tests Table 2 Summary of Data for Lap/Shear Tests However, sizing the lining canvas did not necessarily have the same effect. In fact, in the case of Su (sized polyester-unsized linen), the peel strength was slightly lower, .10 Kg/cm, than in the case Uu (unsized polyester-unsized linen) which recorded .12 Kg/cm. Since the separation in all cases occurred between the original canvas and the lining adhesive, it is to be expected that sizing of the lining canvas should not affect the bond strength significantly. It is difficult, though, to explain the lower readings obtained with Su (sized polyester-unsized canvas). An interesting phenomenon occurred when both the original and lining canvases were sized (Ss): the bond strength was significantly higher than all other samples. It seems in this case that sizing the lining canvas did have a measurable effect on the bonding properties. The second parameter tested was drying time. Table 1 and Figure 1 show that the average peel strength values for 1 hour drying time were slightly higher than the values for 24 hours drying time in three cases (Uu, Us, Su) and lower in one case (Ss). When both the lining components were sized (Ss), the 24 hours drying time produced a stronger bond than the 1 hour drying time: .30 Kg/cm for 24 Ss compared to .26 Kg/cm for 1 Ss. This was confirmed by the lap/shear tests where the same phenomenon occurred.

In general, the lap/shear tests proportionally correspond to the peel tests; that is, when the peel results were high, the lap/shear results were also high and vice versa. One exception is Su which had the lowest peel strength but the second lowest lap/shear strength. 5 CONCLUSIONIT APPEARS THAT in general, sizing of the materials affects the bond strength more significantly than drying time of the adhesive. The strongest bonds were produced when both canvases were sized and the weakest bonds were obtained when the original canvas was unsized. When one component was unsized, bond strengths recorded between .08 and .14 Kg/cm which hovers around the lowest figure offered by Phenix and Hedley7 as a minimum acceptable value for lining (.12 Kg/cm). It is important to stress here that the intent of this study was not to recommend the use of the products tested. Its only aim was to serve as guidance for conservators who use similar materials and methods. Also, because of the complexity of the variables involved during lining procedures, the results should not be analyzed in terms of specific numbers but rather in terms of general trends. In subsequent unpublished testing, the lining procedure was improved by using Dartek instead of mylar as a covering membrane. It was felt that a more even vacuum could be obtained with Dartek because of its “self-sealing” properties. Also, more accurate pressure readings were taken from the top, using a spot magnehelic gauge. Another aspect which would have to be reconsidered in subsequent testing is the use of B-72 dissolved in xylene, as impregnating resin. Personal observation seems to indicate that the evaporation of the xylene from the canvas is much slower than one would suspect. Even though the linings were executed at least 10 days after impregnation, the samples still had strong xylene smell long after lining. It is possible that the increase in bond strength with sized samples may be partly due to the action of xylene still present in the system. Mehra5,6 recommends the use of Plexisol P-550 as consolidant; since this latter is soluble in weaker and faster evaporating solvents, its choice might be better as an impregnating resin. As a last note, quantitative aging tests are not known to have been performed specifically on Lascaux 360 HV. However, Plextol D360 which is believed to be the base resin for Lascaux 360 HV has been tested by E. De Witte et al.8 It is obvious that more thorough aging tests should be executed before the product can be safely recommended. Along this line, our samples have all been peeled half way and we hope to take new readings after at least one year of natural aging. ACKNOWLEDGEMENTSDR. WALTER COBBS for permission to use the Nordson facilities; Mr. William Rehman who provided the data and significant help in carrying out the experiment. Yucel Birol, Graduate Assistant and Dr. Gerhard E. Welsch, Director of the Central Mechanical Testing Facility at Case Western Reserve University for their investigation into the effects of cross head speeds in the evaluation of peel and lap/shear strengths of adhesives. The Mellon Foundation, National Endowment for the Arts and ICA for their partial funding and Peggy Salo for word processing. MATERIALSLascaux 360 HVFine Art Stretchers and Services, Inc., P.O. Box 38, 1064 62nd Street, Brooklyn, NY 11219 Polyester—Terry Polyester #39P & S Textiles, Jordon Rd., Skaneateles Falls, NY 13153 Belgian Linen—1 � 2, plain weave, 8 threads/cm in warp, 15 threads/cm in weft.REFERENCESDianeFalvey, “Practical Cold Lining Developments in Skaneateles, New York.” ICOM Committee for Conservation, 7th Triennial Meeting, Copenhagen, 10–14 Sept. 1984, 84.2.12. BentHacke, “Apparatus for Treatment of Paintings.” ICOM Committee for Conservation, 5th Triennial Meeting, Zagreb, 1978, 78/2/12. Kenneth B.Katz, “The Quantitative Testing and Comparisons of Peel and Lap/Shear for Lascaux 360 HV and BEVA 371.” AIC Journal, Vol. 24, No. 2 (Spring 1985), 60–68. V.R.Mehra “Dispersion as Lining Adhesive and its Scope.” IIC Preprints, Paris Congress, 2–8 Sept, 1984, 44–45. V.R.Mehra, “Cold-Lining and the Care of the Paint-Layer in a Tripple-Stretcher System. Also: Answers to some Questions and Doubts about the Cold-Lining System.” ICOM Committee for Conservation, 5th Triennial Meeting, Zagreb, 1978, 78/2/5. V.R.Mehra, “Cold Lining and its Scope: Some Case Histories.” ICOM Committee for Conservation, 7th Triennial Meeting, Copenhagen, 10–14 Sept. 1984, 84.2.31. AlanPhenix and GerryHedley, “Lining without Heat or Moisture.” ICOM Committee for Conservation, 7th Triennial Meeting, Copenhagen, 10–14 Sept. 1984, 84.2.38. E.DeWitte, S.Florquin and M.Goessens-Landrie, “Influence of the Modification of Dispersions on Film Properties.” IIC Preprints, Paris Congress: 2–8 Sept. 1984, pp. 32–35 GerryHedley and CarolineVillers, “Lining in 1984: Questionnaire Replies.” ICOM Committee for Conservation, 7th Triennial Meeting, Copenhagen, 10–14 Sept. 1984, 84.2.22. A.Howells, G.Burnstock, G.Hedley and S.Hackney, “Polymer Dispersions Artificially Aged.” IIC Preprints, Paris Congress, 2–8 Sept. 1984, pp. 36–43.

Section Index Section Index |