AN EPOXY/MICROBALLOON MIXTURE FOR GAP FILLING IN WOODEN OBJECTSR. Barclay, & C. Mathias

5 APPLICATION5.1 Adhesion of Fill to WoodWHILE VERY LITTLE BLEEDING of uncured resin into the wood is expected, a barrier or resist material can be applied prior to insertion of the fill, assuming, of course, that the wood previously required no consolidation, and thus has no protective barrier already. It is clear from tests on several artifacts that no bond between the fill and the wood is actually required; in an uneven void the cured fill will lock in place physically. In shallow areas it may be necessary to increase adhesion to the wood by application of a layer of fluid epoxy resin prior to insertion of the fill. This should only be done where necessary as it will make the fill difficult to remove and cause damage to the artifact. However, the strength of bonding may be modified by application of layers of other materials. In the following set of tests the fill material was applied to wood samples coated with seven potential bond strength modifiers. Their ease of removal after curing was assessed by attempting to carve them away from the wood

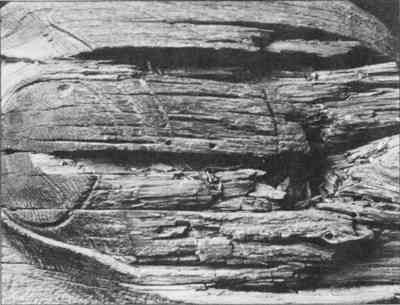

It is apparent that the weaker of these materials will also serve as a resist layer to prevent penetration of the resin into the wood, should this be required. This was a subjective test applied to assess bond strength for a specific application. The results should therefore be treated with caution. Wherever possible the authors prefer to rely upon a mechanical bond, inserting thin wood dowels into existing fine cracks to assist locking if feasible. 5.2 Filling and FinishingVoids should always be over-filled as subsequent layers of the epoxy/microballoon filler do not adhere well. The 1 to 1 ratio and more dense mixtures are easily shaped using woodworker's carving tools. It is difficult to describe the carving characteristics of the fill material except to say that it carves crisply and sharply and is capable of holding very fine detail. When being carved it reminds one of the consistency of very cold ice cream. The weaker 0.5 to 1 mixture has a tendency to crumble when being carved. Should a fill of this weakness be required, it can best be applied to large areas with no fine surface detail. Inpainting can be done with most media, but if phenolic microballoons have been used their reddish colour makes an opaque medium such as water-based acrylics desirable. If a transparent inpaint is required, glass microballoons, which yield a white filler, may be substituted. However, the brightness of the filler may still dictate use of an opaque inpainting medium. A rebuilt mortise in the lintel of a monumental wood sculpture is shown in Figure 7.Figures 8 and 9 show the surface reconstruction of a totem pole.

|