ADHESIVE QUALITIES OF CONSOLIDANTS FOR DETERIORATED WOODTOMOYASU SAKUNO, & ARNO P. SCHNIEWIND

ABSTRACT—The adhesive qualities of commonly used consolidants were investigated by measuring static and impact shear strengths of bonds made in deteriorated Douglas-fir wood. Acryloid B72, Butvar B98, and AYAT were used in 15% solutions, each with two different solvents. Glue joints made with consolidant solutions were not as strong as those made with a polyvinyl acetate emulsion adhesive, but adhesive qualities were judged excellent provided a suitable solvent was used. Choice of solvent was found to be the most important factor, with superior performance of polar as compared to nonpolar solvents. 1 INTRODUCTIONTHE STABILIZATION of deteriorated wooden artifacts of historical or archeological significance may require consolidation of the degraded wood material. To this end, the wood may be impregnated with a variety of natural and synthetic materials. The types of consolidants that might be used and their properties have been thoroughly discussed by Werner (1977). He particularly addressed the strengthening of deteriorated wood by impregnation with thermoplastic resins or other consolidants. Good adhesion between wood and consolidant is one of the most important factors for effective strengthening. Grattan (1980) listed good adhesive qualities as the first among 11 attributes of ideal consolidants. Consolidants should also perform well as adhesives so that loose fragments become reattached in the process of consolidation (Barclay 1981; Nakhla 1986). Grattan (1980) investigated the consolidation of deteriorated wood using different types of thermoplastic resins and concluded that acrylics and polyvinyl butyrals were the most effective. Schniewind and Kronkright (1984) selected several consolidants of the acrylic, polyvinyl butyral, and polyvinyl acetate types to determine their effectiveness in strengthening deteriorated wood. An extensively degraded Indian canoe, a lumjawi, treated with a polyvinyl acetate resin was investigated. In addition systematic tests were made on material from Douglas-fir foundation piles that had been buried for about 70 years and had outer layers severely degraded by bacteria. An acrylic (Acryloid B72) and polyvinyl butyral (Butvar B98) were found to give the greatest improvement in bending strength. Furthermore, Wang and Schniewind (1985) treated specimens from the severely degraded outer layer of piles from the same source with solutions of various combinations of consolidants and solvents. A detailed examination of the bending strength and stiffness of the treated wood was made. While the strengthening effect unquestionably depends in some measure on adhesive bonding strength, this relationship was not investigated directly. The use of the acrylic Acryloid B72 as an adhesive has been examined (Koob 1986), but the solution was prepared at 50% solids content w/w, appropriate Accordingly, it appeared desirable to study adhesive bonding of thermoplastic resins in formulations suitable for consolidation. This study is important not only with respect to the reattachment of loose particles, as already pointed out, but also because the consolidant must be firmly bonded to the material that is being treated in order to obtain the most effective strengthening. 2 EXPERIMENTAL2.1 CONSOLIDANTSTHREE TYPES of synthetic resins generally considered suitable as consolidants for degraded wood were used. These were an acrylic (Acryloid B72), a polyvinyl butyral (Butvar B98), and a polyvinyl acetate (AYAT), their properties are shown in table 1. According to the resin-solvent combination, the consolidants were divided into two series, 1 and 2. In series 1, the solvents were of the polar type: acetone for B72 and ethanol for B98 and AYAT. In series 2, the nonpolar toluene was used for B72 and AYAT, while for B98 a 60:40 mixture (weight basis) of toluene and ethanol had to be used since the manufacturer did not list any suitable pure nonpolar solvent. In all cases, the concentration of the solution was held constant at 15% on a weight basis. At this concentration, solutions have sufficiently low viscosity to be suitable for consolidation treatments, since even at 20% concentrations complete penetration could be achieved in small specimens (Wang and Schniewind 1985). Preliminary experiments using solutions of 10, 15, and 20% concentrations did not reveal any significant differences in the resulting bond strength using a tensile shear test. Therefore the entire study was conducted using only 15% concentration. The viscosity of each solution was measured with a Brookfield viscometer. TABLE 1 Properties of Consolidants 2.2 DEGRADED WOODThe raw material was from foundation piles buried for about 70 years near the San Francisco waterfront. The properties of these piles are given in detail in a separate report (Schniewind, Gammon, and Bendtsen 1982). The remains of four of the piles, originally numbered 5, 9, 12, and 16, were selected for the present study. The length differed for each pile, ranging from 32 ft for pile 16 to 64 ft for pile 5. From each pile, three sections were selected: one from near the butt, one from the middle portion, and one from near the top (as referred to the tree; since piles are driven top first, the top is the end buried most deeply in the ground). Some representative sections are shown in figure 1.

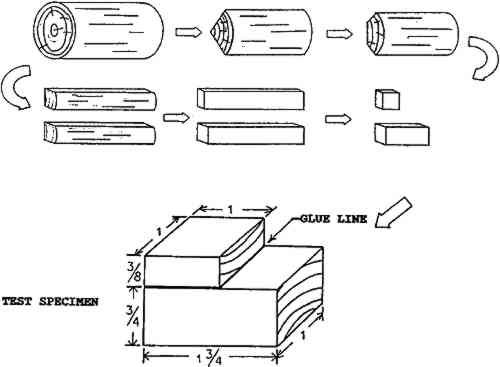

2.3 FABRICATION OF ADHESIVE SHEAR TEST SPECIMENSMaterial to be used for bonding was, as much as possible, taken from the portion nearest the surface of each pile section and conditioned at 70�F and 65% relative humidity. It was desired to evaluate bond quality by shear tests in both a static and an impact mode of testing. To simplify the process, identical specimens were used for both types of test. The machining process for preparing specimen material is illustrated in figure 2. Note that the face to be bonded was always the face closest to the original surface of the piles, that is, the region with the most severe degree of deterioration. The resulting specimen blanks were planed smooth and cut into pairs of small blocks, one measuring 3/8 � 1 � 1 in and the other 3/4 � 1 � 1 3/4 in.

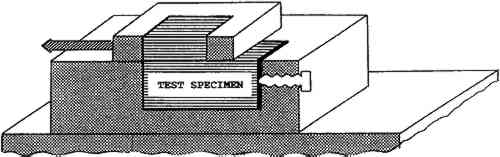

These blocks were then bonded together to form test specimens according to ASTM specification D950 (ASTM 1987), using each of the resins with their respective series 1 Following the same method, a polyvinyl acetate (PVA) emulsion adhesive, a common woodworking glue (Elmer's White Glue), was also used. This adhesive was used at full strength in order to obtain maximum bond strength for comparison. Three test specimens (replications) were made for each combination of treatment, pile, and within-pile location. This procedure would have produced a total of 252 specimens each for both static and impact shear tests. However, the top section of pile 16 yielded only enough material for two instead of three replications for the resins with series 2 solvents, which reduced the total to 249 specimens each for static and for impact testing. 2.4 IMPACT AND STATIC SHEAR BLOCK STRENGTH TESTAfter conditioning the test specimens for one week at 70�F and 65% relative humidity, impact and static shear strength tests were conducted. The impact shear strength test was conducted following the methods specified in ASTM D950, except that an Forest Products Laboratory toughness testing machine with a modified specimen holder as shown in figure 3 was used. The static shear strength test was made using the same test specimen configuration and a universal testing machine with a standard shear test tool. Testing speed was 0.024 in/min of the movable cross-head.

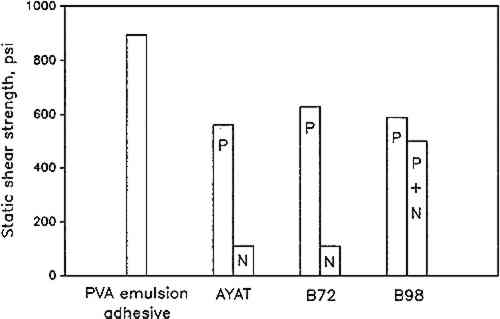

3 RESULTSVISCOSITIES OF resin consolidant solutions are shown in table 1. Values range from 10 to 360 centipoise (CPS), much less than commercial adhesives for wood, which rarely have viscosities of less than 800 and more commonly of 2,000–3,000 centipoise. 3.1 STATIC SHEAR STRENGTHExperiments had been originally designed to detect if differences in degree of deterioration from one pile to the next, or from one location within a pile to the next, might cause differences in adhesive bond strength. Statistical analysis of the data (using a general linear model because of the unequal number of replications) indicated that there were statistically significant differences due foremost to treatment, but also to pile and an interaction between pile and treatment. Location and other interactions were not significant. The data were therefore combined into average values of nine (in some cases eight) observations each and are shown in table 2. TABLE 2 Static Bond Shear Strength by Treatments and Piles The specific gravity of the outer layer of pile 12 was lowest and of pile 16 the highest. There was also evidence that the degree of deterioration was greatest in pile 12 and least in pile 16. The same ordering was found for static bond shear strength, which would be expected as wood strength is proportional to specific gravity, and wood strength is an important factor in bond strength except when there is poor adhesion. Pile 16 gave both the lowest values (B72 and AYAT in toluene) and the highest values (AYAT in ethanol and PVA emulsion adhesive). These values are a major reason for finding the interaction of treatment and pile statistically significant. The between-pile variation, which represents between-tree variation, is part of the total variability that will inevitably be encountered with a natural product such as wood. The data were therefore further combined into average values of 36 (or 35) observations, leaving only treatment effects, and are shown in table 3. Static shear strength was highest for the PVA emulsion adhesive, which should not be surprising since it is the only medium of the seven tested that had been specifically formulated as an adhesive. Next in strength, at about ⅔ the strength of the PVA emulsion adhesive, is the series 1 group of consolidants consisting of each resin with a polar solvent (acetone or ethanol). Butvar B98 with the mixture of ethanol and toluene as solvent was somewhat less strong, but Acryloid B72 and AYAT with toluene gave very little shear strength so that series 2 as a whole had much lower values than series 1. This is further illustrated in figure 4. TABLE 3 Shear Test Results by Treatments

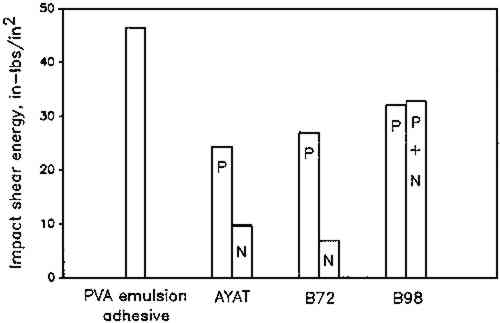

The percentage of wood failure is another indicator of adhesive bond integrity. In industrial settings, wood failure percentages of 100 are desirable, and this level has been virtually achieved with the PVA emulsion adhesive. It thus represents the maximum bond strength that could be obtained with the wood samples of this study since the strength of the bond is almost entirely controlled by the strength of the wood itself. For B72 and AYAT in toluene where shear strength was very low, 0% wood failure was obtained, while for the other systems it ranged from 16% to 28%. 3.2 IMPACT SHEAR STRENGTHThe results of the impact shear strength tests are also summarized in table 3. Results of statistical analysis were the same as for static bond strength, and values were again combined in the same manner and are listed as averages of 36 (or 35) observations. The trends for impact shear strength are much the same as for static shear tests, since the PVA emulsion adhesive gave the highest, and B72 and AYAT of series 2 the lowest values of impact energy consumed during the test, as shown in figure 5. The main difference is that B98 gave almost identical results regardless of solvent and that these results were higher than the B72 and AYAT series 1 values. This result is also reflected in the values for percentage of wood failure, since only B98 among the consolidants showed significant amounts of wood failure, while for B72 and AYAT it ranged from very little to none.

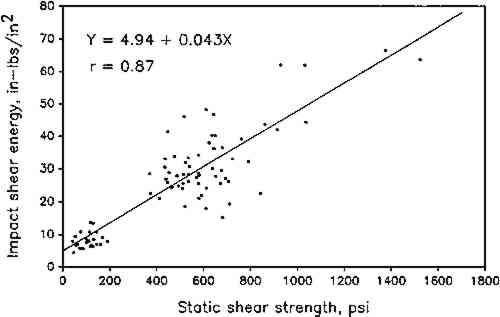

4 DISCUSSION4.1 THE ADHESIVE QUALITIES OF THE CONSOLIDANTSTHE BONDING properties or adhesive qualities of the consolidants can perhaps be evaluated best by comparing them with adhesives ordinarily used for wood. For this comparison a PVA emulsion adhesive was selected and used as the reference standard in this study. There was a significant difference between the bond strength of the consolidants and the PVA emulsion adhesive. This result can be attributed to two factors, both of which relate to the fact that the PVA emulsion adhesive was specifically formulated as an adhesive whereas the consolidant solutions were formulated with other objectives. In particular, consolidant solutions must have low viscosity to obtain optimum penetration, a quality considered undesirable for adhesives. Excessive penetration of an adhesive into In the case of series 2, B72 and AYAT exhibited very poor bonding qualities with the nonpolar solvent, whereas B98 with a mixture of polar and nonpolar solvent had equal impact bond strength and only somewhat reduced static bond shear strength as compared to series 1. Wang and Schniewind (1985) found similarly that B72 and B98 gave generally better strength improvement when used as consolidants in pure polar as compared to nonpolar solvents either pure or in mixture. It is possible that the relatively short time of one week between bonding and testing contributed to the differences in solvent performance, since toluene is known to be retained more tenaciously than other solvents, particularly by Acryloid B72 (Horie 1987). However, it is not believed that this quality can explain more than a fraction of the difference, especially considering that essentially the same results were obtained with both Acryloid B72 and AYAT. Several studies of the effectiveness of consolidants for deteriorated wood in terms of their strengthening capability have ranked Butvar B98 first, followed in order by Acryloid B72 and AYAT (Grattan 1980; Schniewind and Kronkright 1984; Wang and Schniewind 1985). In the present study B98 also performed best in adhesion as measured by impact test, while all three resins had about equal adhesive qualities as measured in static shear test, provided that polar solvents were used. In terms of adhesive qualities, it therefore appears that the most important choice to be made is that of solvent; the choice of resin is secondary. The results of bond tests and strength tests of consolidated wood will not necessarily be the same, since effective strengthening depends not only on adhesion but also on the cohesive strength of the resin. The latter differs substantially among the three resins studied here, with B98 showing the greatest cohesive strength (Schniewind and Kronkright 1984). 4.2 THE EFFECT OF ADHEREND PROPERTIES ON BONDING STRENGTHThe energy absorbed in impact shear by sound Douglas-fir wood was found to range from 48 to 76 in-lb/in2, and for sound wood bonded with PVA emulsion adhesive from 58 to 72 in-lb/in2. The maximum static shear strength parallel to the grain of coast type Douglas-fir is 1130 psi when dry at a mean specific gravity of 0.45 (based on green weight and volume) (Forest Products Laboratory 1987). By comparison, the deteriorated Douglas-fir piles used in this study had specific gravity values ranging from 0.33 to 0.45 (table 2) for the outermost 1-in layer. At the surface where bonding was effected, the specific gravity was most likely even lower than the reported values, since the deterioration progresses from the outside inward. The particular density of each pile is a function of both natural variability and mass loss because of deterioration. Sakuno and Goto (1969) found that the density of wood significantly affects both the static block shear strength and absorbed energy in impact shear. In this study the same trends were obtained for the PVA emulsion adhesive and also when results were averaged over all seven treatments. Since at least part of the observed specific gravity variation is due to deterioration, the condition of the wood will have an important effect on the bond strength that can be achieved. The greater the mass loss due to deterioration, the lower the bond strength will tend to be. However, when used as consolidants, the resins studied are more effective 4.3 CORRELATION BETWEEN ENERGY ABSORBED IN IMPACT SHEAR AND STATIC SHEAR STRENGTHSakuno and Goto (1973) found that there was a highly significant correlation between energy absorbed in impact shear and static shear strength of wood bonded with various types of adhesives. All of static shear strength and impact shear energy data of series 1 and 2, averaged over three (or two where applicable) replications, were plotted against each other, as shown in figure 6. A high correlation coefficient of 0.87 was obtained. This result implies that whichever test is conducted, the value of the other can be estimated from the regression equation.

5 CONCLUSIONSACRYLOID B72, Butvar B98, and AYAT solutions suitable for consolidation were investigated for their adhesive qualities and compared to a polyvinyl acetate emulsion adhesive. The most important factor governing adhesive strength was found to be the REFERENCESAmerican Society for Testing and Materials. 1987. Standard test for impact strength of adhesive bonds, D950–82. In Annual Book of ASTM Standards. Vol. 15.06, Adhesives. Philadelphia: ASTM. Barclay, R.1981. Wood consolidation of an eighteenth century English fire engine. Studies in Conservation26:133–39. Forest Products Laboratory. 1987. Wood handbook: Wood as an engineering material. Agriculture Handbook. No. 72. Washington, D.C.: U.S. Department of Agriculture. Grattan, D. W.1980. Consolidants for degraded and damaged wood. In Proceedings of the furniture and wooden objects symposium. Ottawa: Canadian Conservation Institute. 27–42. Horie, C. V.1987. Materials for conservation. London: Butterworths. Koob, S. P.1986. The use of Paraloid B-72 as an adhesive: Its application for archaeological ceramics and other materials. Studies in Conservation31:7–14. Nakhla, S. M.1986. A comparative study of resins for the consolidation of wooden objects. Studies in Conservation31:38–44. Sakuno, T., and T.Goto. 1969. Studies on the impact strength of adhesives, III, Effects of specific gravity, pH, and wettability. Bulletin of the Faculty of Agriculture, Shimane University, 3:55–60. Sakuno, T., and T.Goto. 1973. Studies on the impact strength of adhesives, IV, Estimation of wood-glue joint by impact load (1). Mokuzai Gakkaishi19(11):533–37. Schniewind, A. P., B.Gammon, and B. A.Bendtsen. 1982. Strength of untreated Douglas-fir foundation piles after some 70 years' service. Forest Products Journal32(11/12):39–46. Schniewind, A. P., and D. P.Kronkright. 1984. Strength evaluation of deteriorated wood treated with consolidants. In Adhesives and Consolidants, ed.N. S.Brommelle, E. M.Pye, P.Smith, and G.Thomson. London: International Institute for Conservation of Historic and Artistic Works. 146–50. Wang, Y., and A. P.Schniewind. 1985. Consolidation of deteriorated wood with soluble resins. Journal of the American Institute for Conservation24:1–24.

Werner, A.E.A.1977. Consolidation of deteriorated wooden artifacts. In International symposium on the conservation and restoration of cultural property. Conservation of wood. Tokyo: Tokyo National Research Institute of Cultural Properties. 17–21. AUTHOR INFORMATIONTOMOYASU SAKUNO was born on May 5, 1939. He received his Bachelor's degree in Agriculture in 1962 at Tottori University and earned his Ph.D. in Agriculture in Kyoto University in 1977. His doctoral dissertation was “Studies on Fracture of Wood Glue Joints under Impact Shear Load.” He has worked at the Wood Research Institute of Kyoto University (1962–64), Shimane University (1964–73) and Tottori University (1973 to present). In 1985–86 he was a visiting professor at the Forest Products Laboratory, University of California at Berkeley. He is presently a forestry science professor in the Faculty of Agriculture of Tottori University, Japan. His main field of study is wood gluing and physical and chemical processing of wood. Address: Faculty of Agriculture, Tottori University, Koyama, Tottori, 680 Japan. ARNO P. SCHIEWIND was trained as a cabinetmaker in Munich, Germany before coming to the United States. He studied wood technology at the University of Michigan, where he received B.S., M.W.T., and Ph.D. degrees. He joined the University of California, Forest Products Laboratory in 1956. He is Professor of Forestry, teaching courses in mechanical behavior of wood and wood-based materials to undergraduate and graduate students. His research has traditionally focused on wood mechanics, but in 1982 he met Dale Kronkright, who got him interested in the application of wood science to the conservation of wood artifacts. Address: Forest Products Laboratory, University of California at Berkeley, College of Natural Resources, 1301 South 46th Street, Richmond, California 94804.

Section Index Section Index |