A TRANSLUCENT WAX-RESIN FILL MATERIAL FOR THE COMPENSATION OF LOSSES IN OBJECTSSUSANNE G�NSICKE, & JOHN W. HIRX

1 INTRODUCTIONThe compensation of losses in objects made from translucent materials such as alabaster, marble, calcite, diorite, and anhydrite has always been challenging. Traditionally waxes, polyester, epoxy, and acrylic resins bulked with a variety of materials and coloring agents to imitate stone have been applied to areas of loss, but to date no satisfactory solution has been found. Waxes tend to collect dust and dirt. Both polyester resins and epoxies are toxic and noxious. If applied directly to the area of loss, they can migrate into and catalyze within the stone. With time, both materials will yellow and can lead to internal staining. These resins are difficult to remove; they only swell in solvents rather than dissolving, and swelling can cause cracking and delamination of the object. The application of lowviscosity synthetic resins sometimes requires the creation of complicated molds. If multicolored or banded fills are required, the work becomes even more complicated. About 10 years ago John Burke, Oakland

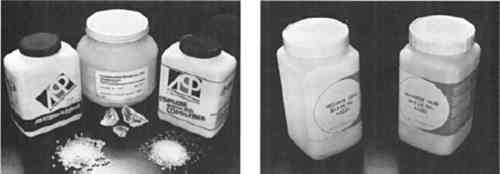

|