MOISTURE RELATIONSHIPS OF PHOTOGRAPHIC FILMP.Z. ADELSTEIN, J.-L. BIGOURDAN, & J.M. REILLY

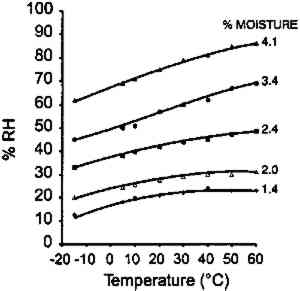

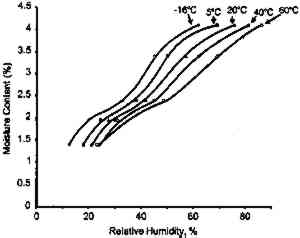

2 EXPERIMENTAL RESULTS2.1 EFFECT OF TEMPERATURE ON MOISTURE EQUILIBRIUM CURVEThe experimental technique used in this investigation was very similar to that employed by McCormick-Goodhart (1994, 1995, 1996). Recent rolls of 100 ft. � 35 mm color motion picture film on .0055 in. cellulose triacetate base were processed according to standard Eastman Color Print ECP-2 processing, then conditioned to five humidities between 20 and 75% RH at 20�C. They were then separately sealed in a 100 ft. metal film can along with a humidity sensor. The sensor was a Vaisala HMP 130Y Series (Humidity and Temperature Transmitter) electrically connected to an outside data logger. Since the volume of film is very large relative to the free air volume, and since air holds very little moisture compared to film, these measurements are at essentially constant moisture content. The temperature was varied between −16 and 60�C. The moisture content of the film was determined by gravimetric analysis, with moisture content being calculated from the film weight after drying the film at 105�C. The moisture content isolines are shown in figure 5. These data do not show the same marked plateau in equilibrium RH with increasing temperature as observed by McCormick-Goodhart (1994, 1995, 1996). However in those previous studies, only gelatin was studied, while in this study data were obtained for the complete film. From the relationships in figure 5, the moisture equilibrium curves in figure 6 were plotted.

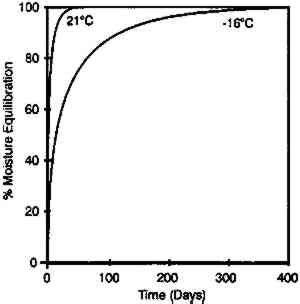

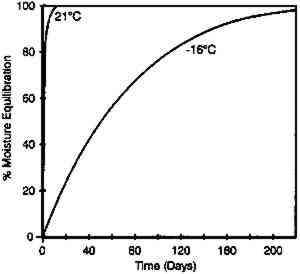

These data duplicate the general relationships previously given for the gelatin binder only. The essential feature is the shift to an increase in equilibrium relative humidity for a constant weight percent water with increasing temperature. This finding has been consistent for all studies (Adelstein et al. 1970; Iwano 1994; McCormick-Goodhart 1994, 1995, 1996). 2.2 RATES OF MOISTURE CONDITIONINGA basic consideration of temperature effects on the moisture properties of film is the rate of moisture conditioning. Although several comprehensive studies have been reported on room temperature (Calhoun 1944; Eastman Kodak Co. 1972), only very limited data have been published on subzero temperatures (Adelstein et al. 1970), and these pertained to film as a single sheet. To obtain information on current materials and on film in a variety of practical storage configurations and enclosures, more extensive conditioning studies have been completed. These featured moisture conditioning curves at −16�C for both motion picture roll film and sheet film. The moisture equilibration rates for the roll films were obtained gravimetrically. Figure 7 illustrates the increase in percent moisture equilibrium expressed in percentage of the total moisture increase after complete equilibrium. The results are given for a 100 ft. � 35 mm motion picture film on .0055 in. cellulose triacetate base, originally conditioned at 21�C and 20% RH. One roll was then placed at 21�C and 50% RH, and the other in a frost-free freezer with air at approximately −16�C and 50% RH. The rolls were not in any enclosure but exposed to the air, with one plane lying on a flat surface. The time to reach 90% moisture equilibrium was 12 days at 21�C and 120 days at −16�C.

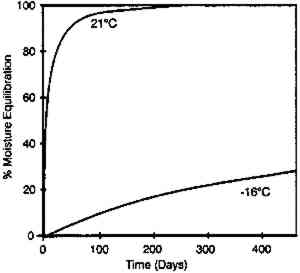

The moisture conditioning rate can be very dependent upon the type of film enclosure used. At both temperatures, the equilibration rates given in figure 7 were very similar if the film rolls were in moisture permeable enclosures such as a cardboard box, a vented plastic can with holes to allow escape of deleterious gases, or an open metal can. However, the situation was very different if the film was in an enclosure with limited access to the outside air. Figure 8 is a similar plot for film in a closed metal can. At 21�C, 90% moisture equilibrium was obtained in 3 months, while at −16�C the film had reached only 20% equilibrium after 1 year. Similar tests on plastic cans produced comparable results. However, the equilibration times are very dependent upon the tightness of the seal between the cover and the can.

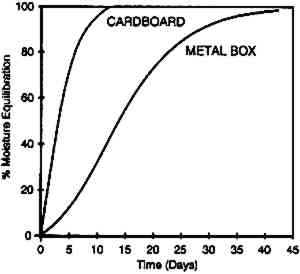

Moisture equilibrium studies were also done on a set of 150 (4 � 5 in.) sheet films on .008 in. cellulose acetate butyrate base that were conditioned to 21�C and 20% RH, enclosed in individual paper envelopes and then stored in a cardboard box. This box was then placed in a 21�C and 50% RH environment. Moisture conditioning was followed using an RH sensor that was inserted within the film pack. The inner sheets required 7 days for 90% moisture equilibration (fig. 9). This experiment was repeated using a metal box instead of the cardboard (fig. 10). While the metal box provided more moisture protection than the cardboard, it was still quite inadequate. The 90% equilibration time increased from 7 to 30 days, a difference not significant for extended times of storage.

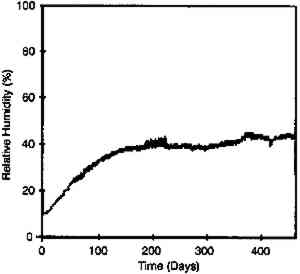

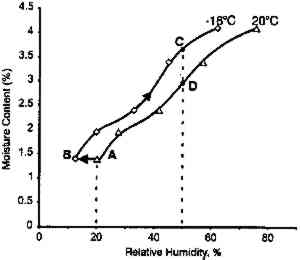

The effect of temperature on moisture conditioning The low-temperature moisture conditioning results are replotted in figure 11, expressing the moisture content as the equilibrium RH of the film measured by the RH sensor imbedded within the film stack. The initial drop in RH from 20 to 10% RH is due to the initial temperature decrease, which is very rapid. This effect is best illustrated in figure 12 by the difference in moisture equilibrium curves at 20�C and −16�C. (Although the data shown in figure 12 were obtained on motion picture film on triacetate base rather than acetate butyrate base sheet film, i.e., the behavior is very similar.) The film is initially at point A, and as it is cooled it goes to point B, which is at a lower equilibrium relative humidity. Subsequent moisture conditioning at −16�C and 50% RH moves the film to point C. An essential feature of this plot is that film initially at point A has 1.4% water, and after final moisture conditioning at point C it has 3.5% water. This shift represents a significant increase.

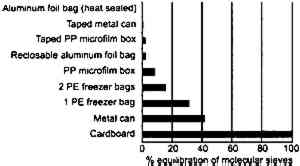

If film is just cooled without any change in equilibrium relative humidity it will also hold more water. Consider film at 20�C and 50% RH (point D). If it is cooled to −16�C at the same relative humidity, its water content will increase from 2.9 to 3.5%. The key conclusion from this phase of the study is that the rate of moisture equilibration at subzero temperature is slow but still appreciable. Moreover, film holds more water at these low temperatures when in equilibrium with the same relative humidity. 2.3 EFFECT OF ENCLOSURESThe data reported in figures 7, 9, 10 and 11 The effectiveness of enclosures was determined by measuring the weight increase of fresh molecular sieves inside enclosures that were placed in a 21�C and 95% RH environment. Molecular sieves are zeolites composed of metal aluminosilicates, marketed by the Eastman Kodak Co. to act as both a desiccant and a scavenger for acetic acid (Ram et al. 1994). They are sold in Tyvek (spun-bonded polyethylene) envelopes that facilitate handling. In this study their desiccant properties were of interest and are used only as an indicator of the moisture barrier of enclosures. The molecular sieve envelopes were initially weighed, placed in various enclosures, and reweighed after 2 months at 21�C and 95% RH. Figure 13 illustrates that heat-sealable aluminum foil bags and taped metal film cans provide a reasonable moisture barrier. However, the common low-density 3 mil. polyethylene freezer bags and untaped 35 mm metal film cans do not offer sufficient protection for film storage. These experiments are still in progress in order to obtain the times required for complete moisture conditioning.

When this study was repeated at −16�C (fig. 14), the moisture gain was obviously much less. However, even at these low temperatures, untaped cans or boxes allow appreciable moisture take-up after only 4 months. They would not be recommended for extended long-term storage in an uncontrolled environment but are satisfactory if the humidity is controlled. This point is discussed further in section 3.2. |