TECHNICAL EXAMINATION OF RENAISSANCE MEDALS THE USE OF LAUE BACK REFLECTION X-RAY DIFFRACTION TO IDENTIFY ELECTROFORMED REPRODUCTIONSGlenn Wharton

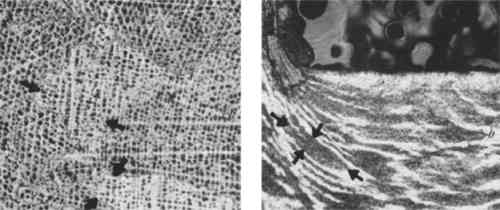

3 ANALYTICAL TECHNIQUES FOR DISTINGUISHING METHODS OF FABRICATIONMETHODS OF EXAMINATION other than visual include the measurement of dimensions, specific gravity measurement, radiography, X-ray fluorescence, scanning electron microscopy, and X-ray diffraction.11 Surmoulages, or reproductions cast from earlier medals, are smaller than their originals because of the shrinkage of cooling metal. The characteristic differences in microstructure of cast, struck and electroformed metal also make metallography an ideal, albeit destructive method of analysis. Although it has previously received little attention in the analysis of works of art, Laue back reflection X-ray diffraction offers a non-destructive method to obtain similar information on metal microstructure.12 Before discussing its application, it must be understood that the grains in electroformed metal are significantly smaller than those of cast and struck metal. The photomicrographs in Figure 4 illustrate the difference in size between typical cast, struck, and electroformed grains. Although the grain size will vary according to fabrication conditions, the grains of cast and struck metal will normally be much larger in scale.

|